-

Keywords"heat",total

1024 records

-

induction heating engine head

Heating engine head Objective Heat steel liners on the head of an engine to remove aluminium casing. Material Steel, 80 mm ID x 190 mm (3.1 in x 7.5 in.) Temperature 650 C (1202 F) Frequency 81 kHz Equipment Power of 35kW induction heating system, …

-

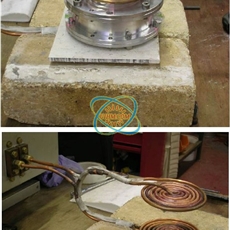

induction heating aluminium susceptor

Heating aluminium susceptor Objective Expand powder into solid form for use in crash helmetsMaterial Microspheric powderAluminium chamber 110mm (4.3 in.) diameter x 35mm (1.3 in.) deep used to hold powderTemperature 150 oC (302 oF)Frequency 54.5 kHzProcess…

-

induction heating titanium blade

Heating Titanium Blade Objective Heat a titanium blade to 500F (200C) to melt and drain the wax from inside the blade.Material 4” length (101.6mm) titanium blades with 1.5” x 0.25” (38.1mm x 6.4mm) metering areaTemperature 500F (200C)Frequency 186 kHzEq…

-

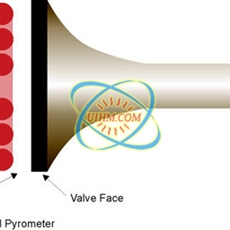

induction heating engine valve

Heating Engine Valve Objective To heat the face of an engine valve head to 900F and maintain the temperature for an extended time, hightemperature stress test.Material Engine valve head (two sizes), temperature sensing paintTemperature 900 FFrequency 223 k…

-

induction pre-heating truck axle

Pre-heating Truck Axle Objective To pre-heat the seam of a truck axle to over 300F within 15 seconds for a welding application and maintain temperature within the welding zone for 15 seconds after the power isturned off.Material Steel truck axle; 350 and 4…

-

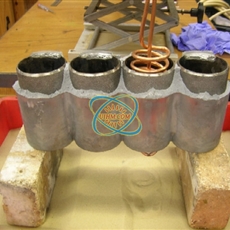

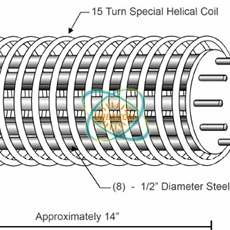

induction heating eight steel rods

Heating Eight Steel Rods Objective Heat eight steel rods simultaneously to 212F (100C) for a molding operation.Material 8 Steel Rods measuring 1/2 (12.7mm) in diameter and 14 (355.6mm) long held in place by 2.5” (63.5mm) diameter Teflon end plates.Tempera…

-

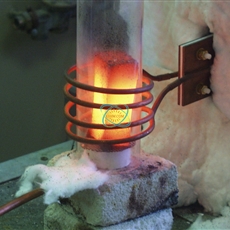

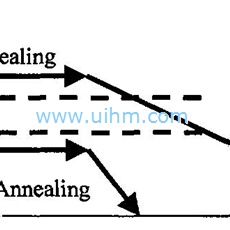

induction heat treating process

Heat treating process Heat treating is an essential phenomenon that is very much needed to manipulate the physical, as well as sometimes the chemical properties of a metal. Though it finds its application in the metallurgical process, heat treating is also…

-

induction heating carbon graphite anodes

Heating carbon graphite anodes Objective Heating carbon graphite anodes to destructively oxidize the parts to process embedded contaminantsMaterial anodes 2.5 x 2.5 x 4 (63 x 63 x 102) h x w x d in (mm)Temperature 1900 F 1000CFrequency 54 kHzEquipment Powe…

-

induction heat treatment of steels

Heat Treating is the process of heating and cooling a steel to obtain desired properties.Various types of heat treatment processes are used to change the following properties or conditionsof the steel:- Improve the toughness – Improve the machinability- I…

-

induction heat treatment process

Heat Treatment process HEAT TREATMENTWe use heat treatments to change properties of metal, or as a method of controlling formation of structures, or expansion/contractional^forces during welding. In heat treating metals and alloys there are many elements f…