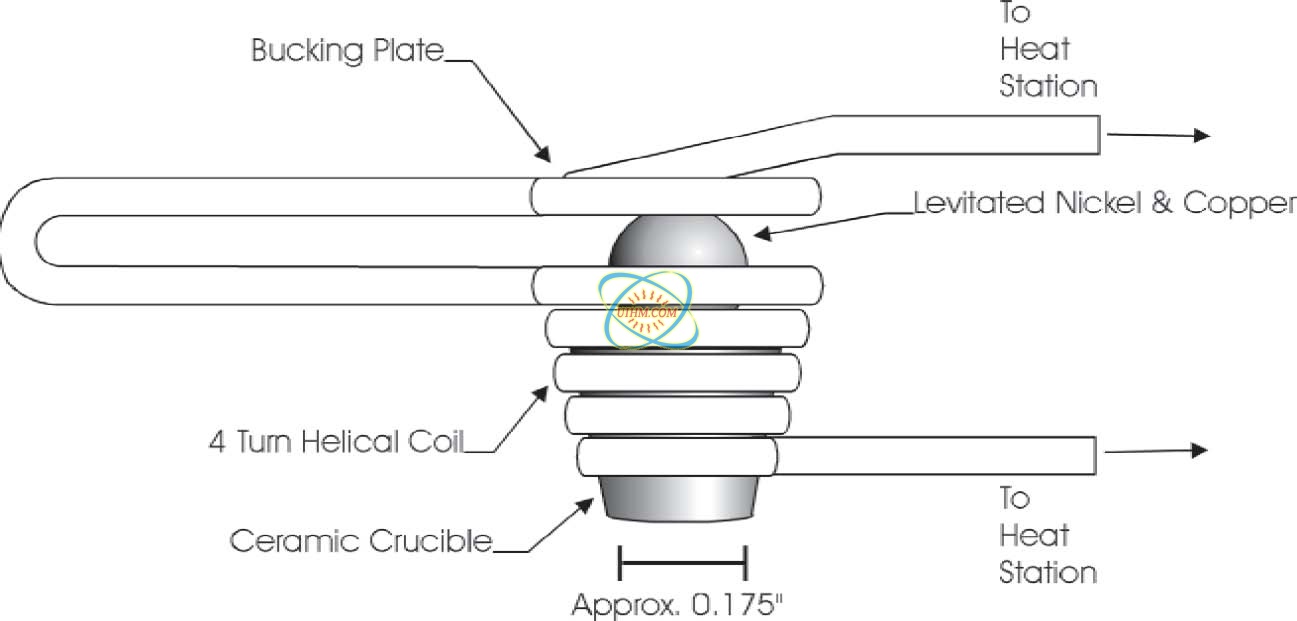

Objective Design a modular electromagnetic levitor (MEL) to aid in the study of RF systems used to process metals in the microgravity of space. Nickel and copper are melted and levitated. A reliable system is to be developed to provide repeatable performance.

Material Copper and nickel 270

Temperature 1982 ºF (1083ºC) copper

2647 ºF (1453ºC) nickel 270

Frequency 409 kHz

Equipment • Power of 6 kW induction heating system, equipped with a remote workhead containing one 1.2μF capacitor

• An induction heating coil designed and developed specifically for this application.

Process A four turn helical coil and a bucking plate are used for levitation. 0.5 g of Copper and 0.5 g of Ni 270 are successfully levitated using the same coil. A stable molten sphere is observed.

Results/Benefits Induction heating provides:

• Hands-free heating that involves no operator skill for manufacturing

• Consistent, reliable melting cycles.

• Even distribution of heating

levitation-melting

Newest Comment

No Comment

Post Comment