Objective To heat a batch of orthodontic parts to 1300°F (704°C) within 1 second in an inert atmosphere for brazing.

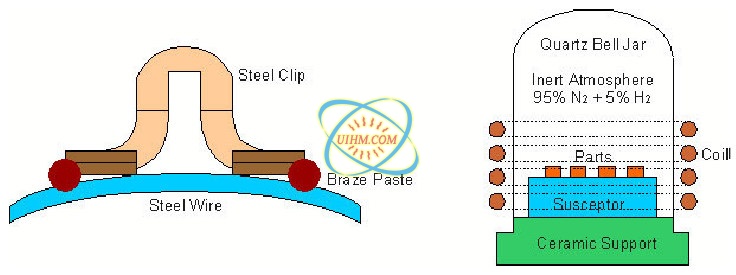

Material Small stainless steel orthodontic parts, silver braze alloy, no flux, 3 1/ 8” (79.3mm) graphite susceptor disk with 1” (25.4) center hole and bell jar made of pyrex or quartz

Temperature 1300°F (704°C)

Frequency 165kHz

Equipment Power of 6KW induction heating system and 0.5 microfarad heat station

Process A four turn helical coil is used to heat parts. Brazing paste is applied to orthodontic parts with a syringe. The parts are placed on the graphite susceptor disk, which is placed on an insulating support in a quartz bell jar. After the jar is filled with inert gas, RF power is applied for 50 seconds at 165kHz to reach the required temperature, followed by a cool-down cycle.

Results/Benefits Induction heating provides:

• Fast, accurate, repeatable heat

• Ability to heat very small areas within precise production tolerances

• Better joint quality, reduced oxidation

• Increased production rates and reduced labor costs (100 parts are brazed in 50 seconds)

Related

induction brazing conducting rod of turbine

induction brass soldering radiator (heat sink)_2

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

induction brazing shoe mold

induction brazing drill bit of transformer

customized RF induction heater for brazing works

© Copyright 2026. uihm.com All Rights Reserved.

Newest Comment

No Comment

Post Comment