Objective To heat an oil suction assembly (steel tubing and filter cap) to 1,850°F (1010°C) within 15 seconds for a brazing application.

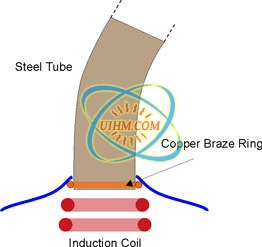

Material 0.125” (3.2mm) diameter steel tube and filter cap assembly, high temperature brazing flux, copper ring.

Temperature 1850°F(1010°C)

Frequency 281 kHz

Equipment • Power of 10KW induction heating system equipped with a remote workhead containing 0.66 μF capacitors

• An induction heating coil designed and developed specifically for this application.

Process A two-turn, specially-contoured helical induction coil is used to heat the tube assembly near the joint area. A copper ring and high temperature flux are then applied to the joint area. Power is applied for 15 seconds until the braze flows.

Results/Benefits Induction heating provides:

• Easy loading and unloading of parts

• Heat very precise areas within production tolerances

• Hands free heating that involves minimal operator skill for manufacturing

Related

induction brazing conducting rod of turbine

induction brass soldering radiator (heat sink)_2

This illustration shows how the connecting sleeve of a plate heat exchanger is inductively brazed on

induction brazing shoe mold

induction brazing drill bit of transformer

customized RF induction heater for brazing works

© Copyright 2026. uihm.com All Rights Reserved.

Newest Comment

No Comment

Post Comment