-

Keywords"n",total

3020 records

-

heat treatment

In recent years this plant is using hardening with preceding induction heating for more than 50% of the total amount of heat-treated parts. These are mainly tractor parts made from 45, 40Kh, 38KhGS, and 33KhS steels. The overwhelming majority of parts (8…

-

heat treating forgings

Forgings are subjected to final heat treatment or intermediate heat treatment to improve the maohinabitity. The processes that occur during heat treatment of forgings can be divided into two groups — processesoccurring at temperatures above and below Ac …

-

induction heating technology in aerospace

The purpose of this Tech Note is to demonstrate the advantages of Induction Heating technology like new Nova Star technology for precision induction heating applications. In each section, we will show how a particular aspect of this new technology makes a …

-

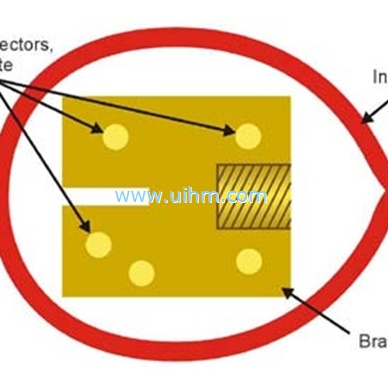

induction soldering steel to brass

Objective Heat an assembly of small, gold-plated steel connectors to a brass block. Approx. 1/8” (3.2mm) diameter gold-plated steel connectors, 1”(25.4mm) square x 1/4” thick brass block ,600F(315.6C),240 kHz Temperature,Frequency,Equipment 6 kW in…

-

why use induction heating

Induction Heating is a GREEN process as it does not emit fumes or CO2 into the environment, emissions are controlled by the electricity generating company at one site and are easy to monitor. The result of only a small proportion of the material bei…

-

advantages of induction heating

Why choose induction heating over convection, radiant, open flame or another heating method? Heres a short summary of the major advantages that modern solid state induction heating offers for lean manufacturing:Optimized Consistency Induction heating elim…

-

induction annealing stainless steel

Induction Annealing stainless steel bread cutting saw blades Objective: Anneal saw blades used for cutting bread, prior to hole punching. Material :.38” (9.6mm) wide and .51” (12.9mm) wide continuous strips of 400 series stainless steel. Tempera…

-

induction shrink fitting

Induction shrink fitting refers to the use of induction heater technology to pre-heat metal components between 150 C (302 F) and 300 C (572 F) thereby causing them to expand and allow for the insertion or removal of another component.Typically the lower te…

-

induction surface hardening

Kelvin Effect, Mean Curvatures and Load Impedance in Surface Induction Hardening: An Analytical Approach including Magnetic Losses Abstract– Kelvin effect(Skin effect) is used in surface hardening produced by induction heating of gears, cam forms, camsh…

-

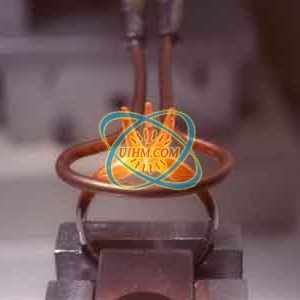

inductor (induction coil) designing

It is within the inductor that the varying magnetic field required for induction heating is developed, through the flow of alternating current. (Induction Coil) design is therefore one of the most important aspects of the overall induction heating machine.…