-

Keywords"in",total

3005 records

-

induction surface quenching works

Induction quenching is the process of quenching steel by heating it. It is done by an alternating magnetic field to a temperature above or within a specific transformation range. It is straight away followed by quenching. This procedure of quenching can be…

-

heat treatment techniques and principles

heat-treatment1 Heat Treatment is generally referred to as heating and cooling of different metals in a controlled way in order to amend both of its mechanical and physical properties without altering the shape of the product. The process involves the m…

-

annealing an effective heating process

There are different types of heat treatment procedures offered by various companies in the market. Few of them are widely applied and are extremely effective. One of the efficient heat treatment procedures is annealing. This process supports an entire indu…

-

how induction brazing works

Induction brazing is a process where two or more materials such as pipe are joined together with a molten space filler metal using an induction heating coil which delivers a very high temperature. The induction brazing process will involve temperature more…

-

induction cooktops save energy, save money for you

An induction cooktop is a cooker which integrates vibrating magnetic energy to create heat. With induction, the heat generated used right into the cooking vessel instead of getting hot through flamable gas or electric coils. The heating vessel used for an …

-

induction furnace cost effective and energy efficient

Raising the temperature of the items break down the complexity of the matter and simplifies the tedious process. Heating melts the hard structure of the substances and minutest of the details can be analyzed. There are many alluring shapes of hard metals.…

-

induction heat treatment services

Induction-Heat-Treatment-Services Shot blasting is creating depressions on the surface of a metal by regularly pelting it with shots of sand or steel balls of a certain diameter. The process is accomplished by employing something like an air gun. A sh…

-

film capacitor module in the application of induction heating system

Induction heating technology used in home appliance on the early and later with high efficiency, energy saving and environmental advantages of growing significantly, with products using the technology is mature and stable, induction heating industry began …

-

mult induction brazing process

Brazing process exudes fumes, emissions and radiations that may be harmful for the people involved in conducting and managing. The people working in this industry are exposed to gases and harmful radiations that are exuded by the brazing of the base metals…

-

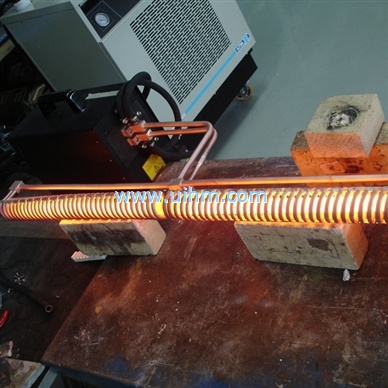

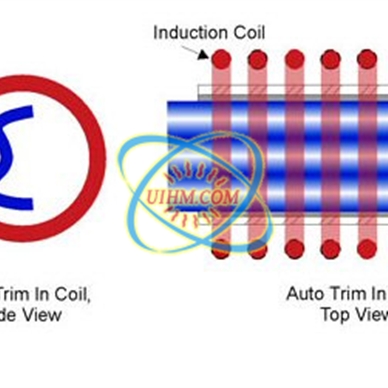

induction heating aluminum auto trim

Objective :To heat various sizes of aluminum auto trim to 500F (260C) at a rate of 30 ft. (9.1m) per minute for curing an adhesive. Material: Magnetic steel and aluminum auto trim parts, coated with adhesive; 1.85” (47mm) ID ceramic tube Temperature :50…