-

Keywords"induction",total

2890 records

-

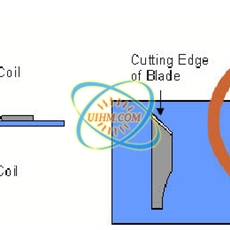

induction hardening surgical blades

Objective To quickly heat a steel surgical blade to 2000F (1093C) within 2 seconds so as to harden the blade edge. Material Stainless steel surgical blades, temperature sensing paint Temperature 2000F (1093C) Frequency 339kHz Equipment Power of 6kW ind…

-

how to choose induction heaters

Induction heating by high frequency Induction heaters output current through the coil generates an alternating magnetic field, through the induction loop on the formation of eddy currents in the metal workpiece, so that the rapid heating, and induction loo…

-

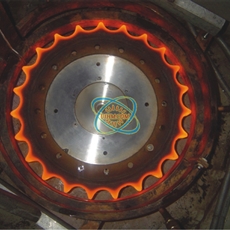

induction hardening applications

UIHM induction surface hardening applications one application: under torsion and bending load of the alternating workpieces requiring surface layer under the Ministry of higher stress than the heart or abrasion on the surface to be made to strengthen the d…

-

igbt induction heater profiles

MF IGBT power transistor module is in the early 1990s, foreign advanced technology, developed a new type of variable frequency induction heating equipment, won the “National New Product Award”. Wide range of applied high-capacity, high efficiency melting…

-

steel induction heat treatment

Overall heat treatment is heating the whole piece, then the appropriate speed cooling, to change its overall mechanical properties of the metal heat treatment process. Roughly the overall heat treatment of steel annealing, normalizing, quenching and temper…

-

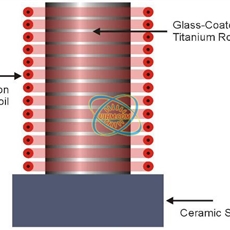

induction hot forming titanium rod

Objective To heat a titanium rod to 1700F (926.7C) within 60 seconds for hot forming. Material Titanium rods, 1.25”(31.8mm) diameter, 5”(127mm) length Temperature 1700F (926.7C) Frequency 70 kHz Equipment • Power of 60kW induction heating system, eq…

-

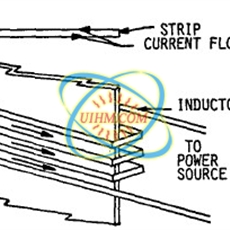

induction stainless steel hot forming

Objective: To heat a stainless steel “J” tape to 3000F from room temperature at a rate of 15 feet per minute. The material is to be heated to aid in forming the “J” shape from flat stock. Material: Stainless Steel “J” Tape measuring 0.562″ wide, 0.…

-

induction melting glass for fiber drawing

Objective To heat a metal susceptor vessel to 2200F within 25 minutes for a fiberglass melting application Material Metal susceptor vessel Temperature 2200F Frequency 300KHZ Equipment Power of 60 kW RF power supply, remote heat statio…

-

induction heat treating

Induction heating has been used extensively for heat treating processes in a variety of metalworking applications.Some of these applications are associated with discrete parts such as shafts, bearings, gears, and hubs. Here, the most common processes are h…

-

induction forge steel rods

Objective To heat the ends of steel rods to 1800F prior to a forging operation. Processing of the rods includes heating, pressing in a two part die to forge the push rod end, and a final heating in a channel coil to temper the rods and relieve the forging …