-

Keywords"on",total

2925 records

-

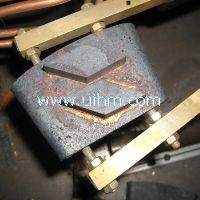

grinding shoe by induction brazing

This application is induction brazing for Grinding Shoe, it brings quick speed and wonderful welding effect. Grinding Shoe by induction BrazingGrinding Shoe

-

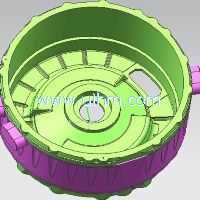

inducton shrinking fit for 2 shells

induction heating is a very good method for shrinking fit work, quick speed, none-contact,environmental protected.shrinking fit for 2 shells

-

induction brass soldering for pot bottom

Induction heating is widely used for brass soldering, its better than common heating ways like gas welding.induction brazing copper scewinduction brass brazing nutinduction brass brazinginduction brass soldering

-

8 turns induction coil for melting platinium

This coil has 8 turns, it is 53 and O,D.67 and it is used for melting platinium.This coil need transformer with 2 turns on secondary.8 turns induction coil with 2 turns secondary coil for melting platinium

-

double head coil for induction hardening machine

double head COIL FOR INDUCTION HARDENING MACHINEThis video is application of hardening axle by UM-20AB-UHF High Frequency (>100KHz) induction heating machine with twin induction coils (double heads), this bring a high quality and fast speed hardening wo…

-

various shape of induction coils

induction coil design 1Base Induction Coil Design and Theory Induction Coil Design and Fabrication

-

various induction coil for different application

different induction coilHigh frequency induction heating of billets of titaniuminduction coil designinduction coil for inside heatinginduction coil for quenchinginduction coil for temperinginduction coil segmentinduction coil with magnetic coreInduction he…

-

induction hot fit massive complex shapes

High-frequency induction heating is successfully used for shrink-fit and renting unique details (bandages, all bore rotors of turbine parts, parts with bore powerful engines, bearing rings, propellers of ships, bore different parts forging equipment, etc.)…

-

high frequency induction brazing copper bars for the stator winding

High frequency induction brazing is an energy-saving technology. High power densities that are implemented in induction heating, allow to rapidly heat the local area to the soldering temperature 600 - 1200 C, at a cost of minimum energy process compared t…

-

high frequency induction brazing pipes for copper and iron alloys

High frequency induction brazing is an energy-saving technology. High specific power, which are implemented by induction heating to quickly heat the local area to the brazing temperature 600 - 1200 C, spending at the lowest energy in the process compared …