-

Keywords"be",total

113 records

-

induction brazing steel tube

Objective To braze a steel tube to a steel “T” fitting Material 1” (25.4mm) diameter steel tubing, steel fitting, braze slug and black flux Temperature 1400F (760C) Frequency 198 kHz Equipment • Power of 15kW induction heating system, equipped with…

-

induction brazing copper tube & pipe

Objective Braze brass fitting with o-ring to various diameters of copper tube. Material Various copper tubes ranging from 3/8” to 7/8” diameter and 2-3’ long, female brass fittings with o-ring, silver solder rings and glass beaker. Temperature 1300 F …

-

induction brazing bourdon tube

Objective To braze a thin copper oval tube to a brass fitting at 1400 F and to cap the other end of the copper tube with a brass plate.Material Brass fitting – 0.875 in2 and 2.5 in long (22mm2 x 64mm) Copper tube 0.01 in (0.254mm) wall Brass plate 0.10 i…

-

induction brazing carbide shaft to steel tube

Objective Braze a carbide shaft to a steel tube Material Carbide shaft 1/8” to 1” diameter (varying sizes) Steel tube 3/8” to 1 ” OD Silver solder braze Temperature indicating paint Temperature 1400 F for 60 seconds Frequency 220 kHz Equipment Pow…

-

induction braze copper tube to brass fitting

Objective To use induction heating to braze a copper tube to a brass fitting using a preform braze wire. Processing is to occur under an atmosphere of Nitrogen and 4% Hydrogen gas. The braze preforms melt at 1190F, but the parts need to be kept below 1300F…

-

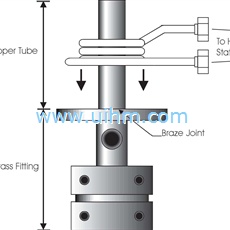

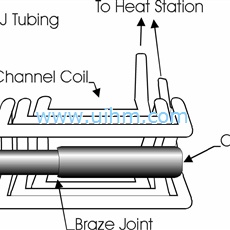

induction brazing copper tube

Objective To braze a copper tube ( 3/8″ OD by 2-4″ long) into a 3/8″ fitting in less than 10 seconds. Heating must take place in a channel type coil to allow for easy loading of parts. Material Copper Tubing and Fitting with Braze and Stay Silv White…

-

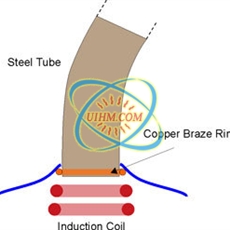

induction brazing steel tube with copper ring

Objective To heat an oil suction assembly (steel tubing and filter cap) to 1,850F (1010C) within 15 seconds for a brazing application. Material 0.125” (3.2mm) diameter steel tube and filter cap assembly, high temperature brazing flux, copper ring. Tempe…

-

induction annealing steel tubes

Objective To heat steel tubes to 2000 F (1093 C) in an inert atmosphere Material 0.1” (2.54mm) diameter stainless steel tube Temperature 2000 F Frequency 333 kHz Equipment • 10 kW induction heating system, equipped with a remote workhead containing…

-

induction bending and hot rolling

Induction Bending And Hot Rolling the 1620mmX40mm steel pipe in the West-East natural gas transmission project. Induction bending is also referred to as hot rolling, but there are some differences between the two processes. Induction bending is an ef…

-

why induction brazing is better

different induction brazing workInduction Brazing for Aviation Fan blades and blades for boxes, different parts for numerous components in hydraulic systems and fuel systemsInduction Automotive Brazing Copper or steel components like brake linings and …