Induction Heating carbon graphite anodes

Views Send Enquiry

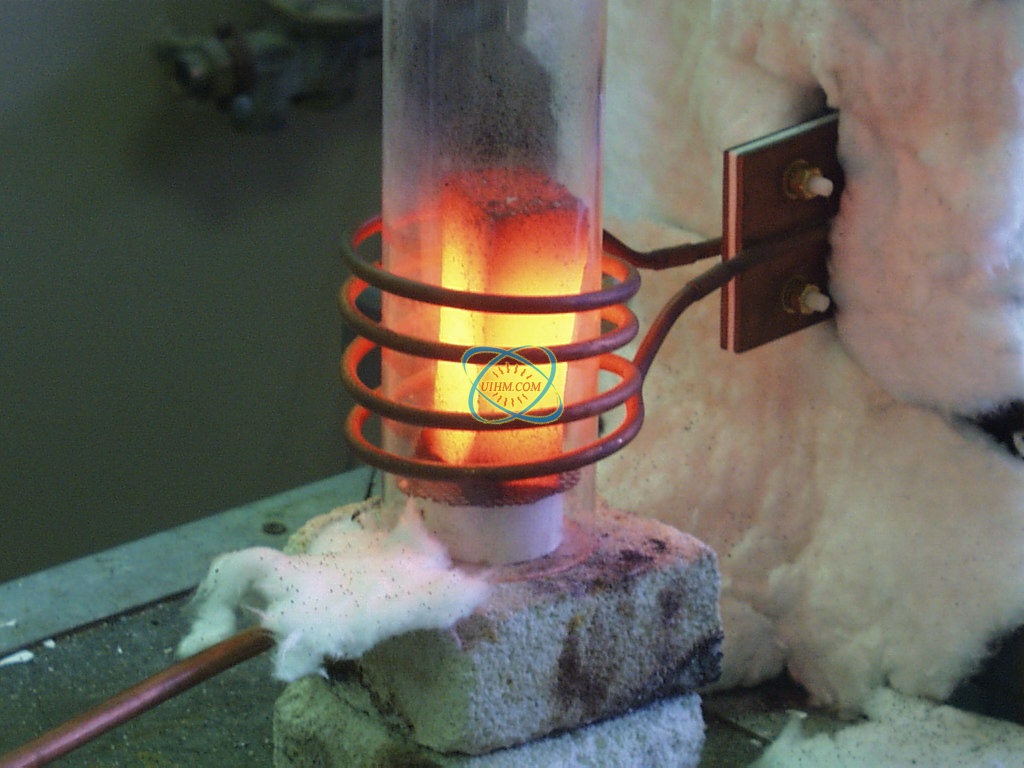

Objective Heating carbon graphite anodes to destructively oxidize the parts to process embedded contaminants

Material anodes 2.5 x 2.5 x 4 (63 x 63 x 102) h x w x d in (mm)

Temperature 1900 °F 1000°C

Frequency 54 kHz

Equipment Power of 70kW induction heating system, custom multi-turn helical coil, 4 cap 1.0μF workhead

Process An air purge system is used to provide fresh air (~25 f3/hr) to the part during the heat cycle and to provide a swirling action for maximum contact with the surface of the anode.

The anode is placed inside the induction-heating coil and heated to a temperature of 1000°C. After 2.5 hours, the anode

burns to about 0.375 inch diameter piece.

A pyrometer/controller is used to provide constant temperature as the anode reduces in size.

Results/Benefits Induction heating allows this process to be very efficient and controllable

Heating carbon graphite anodes

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Hot

induction heating bolts from turbine

induction debonding from steel rod

induction debonding rubber

Releasing Fixture by Induction Heating

Remove plastic coating from steel tubes by Induction Heating

Induction Heating catheter tipping die

Induction Molding for teflon catheter tip

induction melting for crystal growth

Newest Comment

No Comment

Post Comment