Induction Bonding Steel Clips

Views Send Enquiry

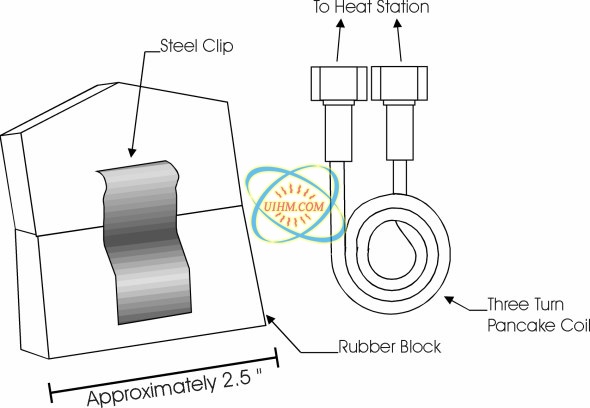

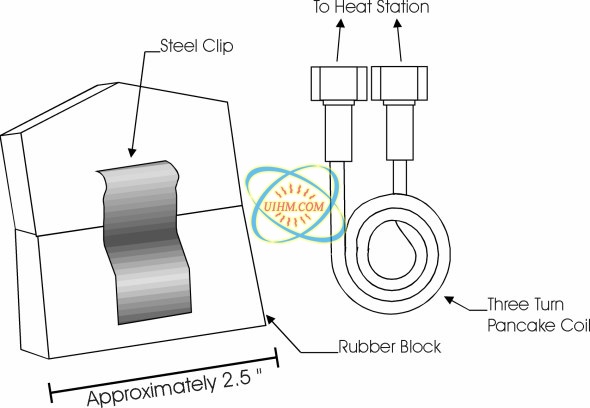

Objective To heat metal clips and press-bond them into rubber seals. The metal needs to be heated to 250°F to 350°F with a cycle time not exceeding 3 seconds

Material Steel clips and rubber sealer blocks

Temperature 250°F to 350°F

Frequency 373 kHz

Equipment Power of 6kW power supply including one remote heat station with one 1.2 μF capacitor using a specially

designed 3-turn pancake coil Process As illustrated below

Results Heating time of 1.5 seconds was attained; shorter heating times are possible due to fast response of the power supply. Bond formation is acceptable due to the even heat pattern produced through induction heating.

Material Steel clips and rubber sealer blocks

Temperature 250°F to 350°F

Frequency 373 kHz

Equipment Power of 6kW power supply including one remote heat station with one 1.2 μF capacitor using a specially

designed 3-turn pancake coil Process As illustrated below

Results Heating time of 1.5 seconds was attained; shorter heating times are possible due to fast response of the power supply. Bond formation is acceptable due to the even heat pattern produced through induction heating.

Good

Bad

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Newest Comment

No Comment

Post Comment