Induction Heat Television Picture Tube Glass

Views Send Enquiry

Objective: The incorporation of solid state RF induction heating into the television picture tube industry, specifically the insertion of attachment pins into the already formed picture tube glass panel. Four pins are to be heated

simultaneously and uniformly for the insertion process. Overall goals include heating each pin to 20000F within two (2) seconds and allowing for insertion of the pins into the glass.

Material: Hollow steel pins measuring 1/2″ OD by 7/16″ high.

Temperature: 20000F

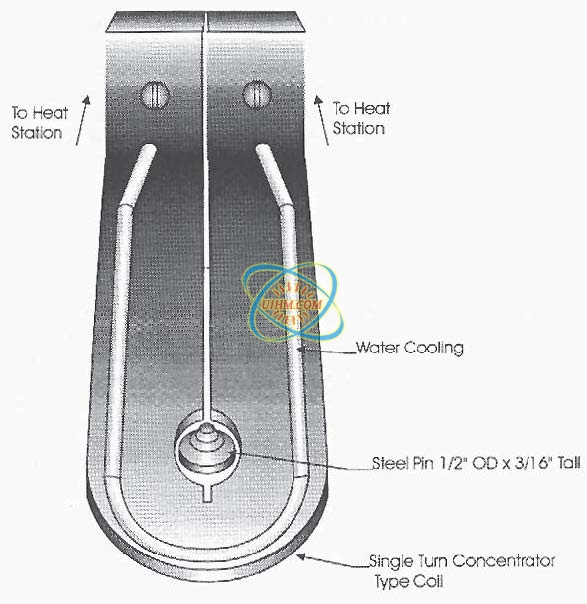

Application: Through extensive laboratory work, a single turn concentrator type coil was developed to integrate with the Power of 6KW, 6 kW high frequency output solid state induction power supply. Using four (4) individual coils and four (4) Power of 6KW, 6 kW HF power supplies (contained within an SP 3/HF x 4 rack cabinet) the following results

were achieved:

* 20000F was reached on each pin simultaneously in two (2) seconds.

* Uniform temperature gradient measurements were taken using an IR optical pyrometer.

* The single turn concentrator coil design allows for the pins to be inserted into the glass after heating.

Equipment: Power of 6KW, 6 kW output solid state induction power supply rack unit containing four (4) Power of 6KW units. Included with each power supply is one (1) remote heat station containing one (1) capacitor with a value of 1.2 μF and one (1) single turn concentrator style coil.

Frequency: 720 kHz

Heat Television Picture Tube Glass

Related Content

Air Cooled clamp coil (half-open coil) for preheating gas pipeline

induction coating by air cooled clamp induction coil

Remove plastic coating from steel tubes by Induction Heating

Releasing Fixture by Induction Heating

U shape air cooled induction coil by UM-100C-HF for pipeline preheating

induction quenching with custom-design inductor

induction brazing diamond segment

induction brass soldering copper plate_2

Newest Comment

No Comment

Post Comment